An irrigation system allows you to not only water your plants but also fertilize them conveniently and efficiently. Below, I will present various technical options in this area.

All the methods described use liquid fertilizer, which is added to the watering can. These liquid fertilizers are generally water-soluble and can therefore be mixed with water. Some systems also allow the use of fertilizer granules, which are dissolved in the water before watering. Compared to fertilizing with conventional fertilizer, fertilizing with liquid fertilizer offers the following advantages:

- Less time required

- Relatively user-friendly and easy to apply

- Effective and consistent results

- In dry weather, the fertilizer is absorbed into the soil immediately

- It works very quickly (however, the effect is shorter-lasting than with solid fertilizer, so more frequent fertilization is necessary)

To prevent the risk of the fertilizer-mixed water flowing back towards the water source, a check valve should be installed between the water source and the fertilization system. If using drinking water directly from the drinking water system, the stricter regulations regarding drinking water protection must be observed.

Three Types of Systems

Regarding the basic operating principle for fertilizer application, three types of systems can be distinguished:

- Vacuum-based systems

- Pump-based systems

- Very simple systems where the fertilizer is simply flushed from the fertilizer container by means of a water supply

The systems in the first group deliberately create a vacuum to “suck” the fertilizer from the fertilizer container into the irrigation circuit, while those in the second group accomplish this with their own pump. The vacuum-based systems are usually less expensive to purchase and generally also relatively easy to use. The systems in the last group are even simpler, where water is simply added to the fertilizer container and flushed out again as a water-fertilizer mixture. These are specifically aimed at private end users with a focus on ease of use and are not suitable for professional applications.

I will present the different options available on the market below, starting with the simplest and progressing to more complex systems. First, three solutions for manual application, apart from automatic garden irrigation.

Liquid fertilizer container with spray attachment

Liquid fertilizer bottles and canisters (Amazon Link) are available on the market, to which a standard 1/2-inch hose can be directly connected. The fertilizer is automatically added to the watering can in a preset ratio and applied using the spray device integrated into the container. If a water connection and hose are already available, this option can be implemented with zero investment costs.

Special Garden Hose Nozzles with Fertilizer Dispenser

Fertilizing with a special garden hose nozzle equipped with a fertilizer reservoir, which can be refilled, works similarly to the previous method, but even more sophisticated and refined. You connect the hose nozzle to the garden hose and the desired dosage can be adjusted on the nozzle itself; watering is otherwise done as normal. Alternatively, such a garden hose nozzle (Amazon Link) can also be used with cleaning agents for car washing. They cost approximately $15 to $30.

Pump sprayers

These offer a possible alternative to using liquid fertilizer when a hose connection is unavailable. Pump sprayers (Amazon Link) are typically available in 1-gallon or 2-gallon capacities.. How they work: Water and fertilizer are added to the spray bottle, the bottle is sealed, and the pressure inside is increased by pumping several times. This is achieved using a piston with a handle inside the bottle. This piston functions like a piston pump. Because it is relatively large, a small amount of air is pumped into the bottle with just a few pumps, quickly building up the required pressure.

A spray lance is connected to the spray bottle via a hose. Pressing a button releases the pressurized liquid.

These pump sprayers can also be used to apply weed killer or cleaning foam, in addition to fertilizer.

Integrating Fertilization into an Automatic Irrigation System

The fertilization systems presented below are designed for permanent integration into an irrigation system, allowing fertilization to be carried out automatically during watering without any further manual intervention.

Fertilizer Dispenser

These are self-contained systems for private use that can be used immediately in the irrigation system without additional components. Due to their limited capacity and maximum pressure, they are primarily suitable for micro-irrigation. They consist of a fertilizer dispenser with a water inlet and outlet. Examples of this group include the Gardena fertilizer injector and the Chapin fertilizer injectors (Amazon Link).

Gardena Fertilizer dispenser

To use, simply connect the fertilizer dispenser to the irrigation pipeline. If the system is designed for micro-irrigation with a low maximum pressure, a pressure reducer must be installed upstream. Pour the fertilizer into the reservoir and activate the fertilizer mixing mechanism using the lever. Water flows into the reservoir at the bottom, mixes with the fertilizer, and is then flushed out as a water-fertilizer mixture through the outlet at the top of the reservoir and distributed via the irrigation system.

A dosage ratio cannot be set. Instead, the amount of fertilizer to be added is calculated based on the water requirements of the planned irrigation cycle and the liquid fertilizer manufacturer’s dosage recommendation, and then poured into the reservoir. For example: If an irrigation cycle with a water consumption of 10 gallons is planned, and the liquid fertilizer manufacturer’s dosage recommendation is 0.004 gallons or 0.5 fl oz per gallon of water, then 0.04 gallons or 5 fl oz of fertilizer should be added to the fertilizer reservoir. If water consumption is unknown, it can either be measured or, in the case of a micro-irrigation system, estimated based on the number of drippers used (e.g., if the system uses 40 0.5 gallon drippers, then the water consumption is 20 gallons per hour).

Some systems include a filter that, in addition to liquid fertilizer, also allows the use of filter granules that dissolve in the water flowing through them. The filter prevents undissolved granules from entering the irrigation system.

The fertilizer dosage in such systems is not constant; it is highest at the beginning of the irrigation cycle and then gradually decreases. As the irrigation cycle progresses, the fertilizer-water mixture will contain very little fertilizer.

A crucial factor when choosing a system is the capacity of the reservoir. The reservoir of the Gardena fertilizer dispenser, for example, holds a maximum of only 10 fl oz. This means that refilling is absolutely necessary before each watering cycle. However, the small size might also be insufficient for a single watering session, requiring multiple refills within that cycle. Chapin also offers models with larger reservoirs, which are also suitable for slightly higher pressure (up to 40 psi compared to 22 psi for Gardena).

Gardena Fertilizer Dispenser in a Quick Test

For this article, I put the Gardena fertilizer dispenser through a short test. First, let’s look at what’s included: For around $20, you get the device itself along with two adapters that allow you to convert the inlet and outlet from the larger 1/2 inch supply pipe to the smaller 1/4 inch distribution pipe, so you can also connect the smaller distribution pipe as an alternative. A brief instruction manual is also included, but the operation is essentially self-explanatory.

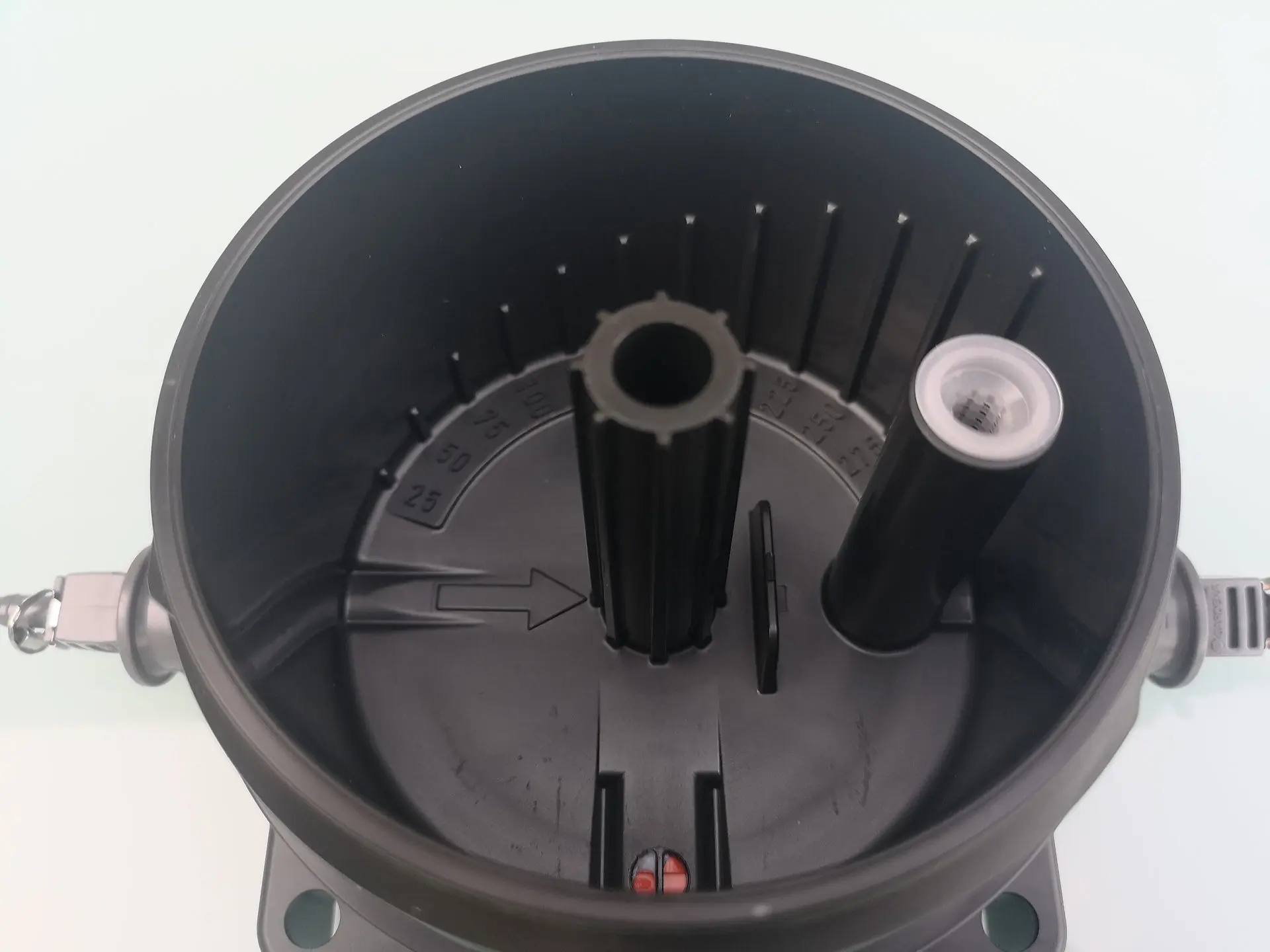

The fertilizer dipsenser appears to be of high-quality construction, with a heavy, well-fitting plastic lid. It has a maximum capacity of 0.08 gallons. A practical feature: When filling, you can see how much fertilizer has already been added thanks to the markings on the side, making it easy to approach a specific target amount.

A look inside with the practical fill level markings

I simply placed the fertilizer dispenser in front of a micro-irrigation zone. Specifically, after the pressure regulator, as the pressure inside the device must not exceed 22 psi.

This is how to connect the device (pressure regulator on the left).

The installation direction is indicated by an arrow on the device. Before starting, the lever must be set to “Mix” and then irrigation can begin. The other setting, “Service,” is for draining the water from the bottom of the reservoir to empty it. In my test, the operation worked flawlessly, but the micro-irrigation area I watered would probably be too large for real-world use, as evidenced by the fact that the fertilizer solution was washed out of the device in no time. In practice, I would doubt that the fertilizer would then be distributed evenly to the plants.

Conclusion: The Gardena fertilizer injector works reasonably well, but in my opinion, it is really only suitable for very small micro-irrigation applications, such as on a balcony or a small patio. As soon as the area becomes larger, I would recommend a system with a larger reservoir.

Alternatives to the Gardena Fertilizer Mixer

Besides Gardena, I am only aware of the Chapin Hydrofeed devices with the same principle. There is the Hydrofeed 4700 to 4702 (Amazon Link), a device that is built on the same principle as the Gardena fertilizer mixer, but is designed for hanging rather than standing installation. It is offered with fertilizer capacities of 16, 24, or 32 ounces. And then, from the same company, there is the much larger Hydrofeed 4720 with a comparatively large 2 gallon tank and an injector section separate from the tank.

Venturi Injector

This method of fertilization, known for centuries, utilizes a physical principle: When a liquid is forced through a constriction, its velocity increases at that point, while the outward pressure exerted by the liquid decreases. This can be explained by the formula: Total pressure = Flow pressure + Static pressure. Therefore, if the flow velocity (= flow pressure) increases, the outward pressure (= static pressure) must decrease. If the constriction through which the water is forced through a pipe is narrow enough, there is no pressure at all on the outer walls; instead, a vacuum is created. This means that if there were a hole in the outer wall at this constriction, no water would escape; instead, if you placed your finger on it, you would feel a suction.

The so-called Venturi nozzle utilizes this principle. A smooth-walled pipe is significantly narrowed in the middle, and a suction hose leads from this constriction, utilizing the vacuum to draw in a liquid or gas.

Example of a Venturi injector in use

Alternatively, the Venturi nozzle can also be installed in a bypass branch that diverts from the main line. Such a bypass has the advantage that only a portion of the water flow passes through the Venturi nozzle (allowing for larger volumes of water) and that a valve installed in the main line can be used to slow down the water flow, creating a controlled pressure differential and thus controlling the intensity of the fertilizer application.

In agriculture, such Venturi nozzles have been used for fertilization for many decades. Their advantage: They utilize existing water pressure to deliver the liquid fertilizer, and they are very easy to install and compatible with fertilizer tanks of virtually any size. Disadvantages: The Venturi principle requires pressure, and the fertilizer intake results in a loss of water pressure. Furthermore, the fertilizer dosage is pressure-dependent and therefore not constant under fluctuating pressure.

More information on how the Venturi injector works, including a short test report, can be found in a separate article: Fertilizing with a Venturi Injector

Differential Pressure Fertilizer Tanks

These systems function similarly to the previously described fertilizer injectors, but are significantly larger and additionally utilize a bypass (diversion) to create a controlled pressure differential. This allows for precise control over the force with which the water-fertilizer mixture is drawn from the tank. Part of the water flow continues directly through the main line, while another part takes the detour via the new bypass into the fertilizer tank. There, the water mixes with the fertilizer, and the resulting mixture is then transported and distributed.

A valve is installed in the main line at the bypass point to slow down the water flow. The greater the slowdown, the greater the pressure differential between the tank inlet and outlet, and consequently, the stronger the water-fertilizer mixture is drawn from the tank.

As with fertilizer injectors, the dosage in differential pressure tanks is not constant: The fertilizer concentration in the dispensed water is high at the beginning, decreases continuously with the water flowing into the tank, and is very low at the end of the irrigation. Therefore, as with fertilizer injectors, there is a risk of overdosing fertilizer in some areas and underdosing it in others.

Compared to a Venturi injector, the application is somewhat simpler. However, significantly less controlled fertilization is possible. The generation of differential pressure also results in a pressure drop in the fertilizer tank.

Dosing Pumps

These are mechanical pumps, meaning they operate without an electrical connection. They are also known as “Positive Displacement Injectors.” The principle is similar to that of another type of piston pump, the traditional hand pump. Water from a pump or the mains water supply flows into the pump and drives the piston. The piston’s stroke adds fertilizer to the water, and the water-fertilizer mixture is then pumped on the other side of the pump. The dosing ratio can be adjusted on the pump.

Dosing pumps are a very professional method of fertilization and have the significant advantage that the dosing ratio remains constant regardless of the water pressure and flow rate, as the same amount of water and fertilizer is mixed with each up-and-down movement of the piston. However, they are considerably more expensive than Venturi nozzles. As with Venturi nozzles, dosing pumps also experience a certain water pressure loss, which depends on the water flow rate. For example, the Tefen Mixrite TF-125-04 has a pressure loss of 3 psi at a flow rate of only 50 gallons per hour and 17 psi when operating at the maximum flow rate of 660 gallons per hour.

Dosing pumps from brand-name manufacturers like Dosatron or Tefen start at around $500, but generic models are also available on Amazon and eBay starting at approximately $150 (Amazon Link).

Electric Dosing Pumps

These are the top-of-the-line fertilization systems. They function on the same basic principle as the previously described dosing pumps, by dispensing water and fertilizer in a predetermined ratio and then pumping it onward. The only difference is that the drive is electric, for example, with a pump controlled by the water flow. They are significantly more expensive than their manual counterparts and therefore generally unaffordable for private users.

Conclusion and Recommendation

Differential pressure fertilizer tanks are only used in a few regions of the world and are rarely available on the market. Due to their high price, electric dosing pumps are not a viable alternative for private users. This leaves you with four basic alternatives:

- Manual watering using special fertilizer sprayers, fertilizer containers with spray attachments, or pump sprayers

- Fertilizer mixing dispenser

- Venturi nozzle

- Mechanical dosing pump

If you don’t want to invest much, have minimal setup effort, and don’t mind a little manual work when fertilizing, then the options mentioned at the beginning of this report for integrating liquid fertilizer into a manual system are worth considering.

For small and medium-sized micro-irrigation systems, fertilizer mixing dispenser offer a very simple and effective alternative. The container is simply placed in front of the micro-irrigation area, and the fertilizer is gradually flushed out during watering. For small-scale applications, where only a few plants on a balcony or patio are being micro-irrigated and the water flow is low, the Gardena fertilizer dispenser is suitable. For medium-sized systems, Chapin fertilizer injectors are recommended, and for larger micro-irrigation systems, the large 2 gallon Chapin Hydrofeed 4720 tank is ideal.

A more professional fertilization method, allowing for active regulation of fertilizer dosage and ensuring consistent application, is possible with Venturi injectors. These have been used in agriculture for many decades and can be easily integrated into an existing irrigation system using a bypass. The tank size is flexible, as any suitable container can be used. A more powerful pump is required, as the Venturi nozzle noticeably reduces water pressure.

For home users, the ultimate solution is the mechanical dosing pump. This system is significantly easier to use than the Venturi injector and guarantees consistent dosing even under fluctuating pressure. The fertilizer dosage can be easily adjusted via a lever. However, especially with brand-name equipment, it is many times more expensive than the Venturi injector.