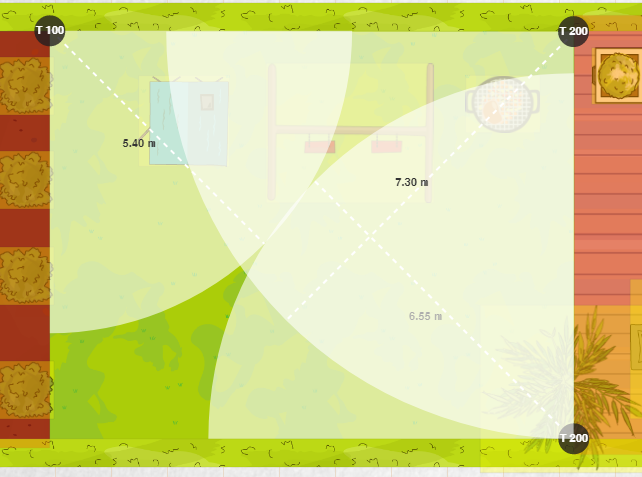

In order to achieve the most even pressure distribution possible, the sprinklers are ideally not simply connected to the pipeline one after the other, but in systems that ensure the most even pressure distribution possible. Otherwise, the first sprinkler in line could take significantly more pressure than the last, resulting in uneven and unplanned throws. Here is an example of such an in-line system:

The sprinklers are supplied with water from the pipeline one after the other in a row

Here 6 sprinklers (shown as filled circles) have to be supplied. The pipeline first has to bridge the distance from the water connection to the beginning of the irrigation sector. It is then connected directly to the first sprinkler and then runs through the five other sprinklers one after the other. It ends after the sixth sprinkler.

The following 2 systems ensure a more even pressure distribution compared to such an in-line system and can also bring an advantage in terms of pressure drop in the pipeline, as this is always measured at the most distant sprinkler in the irrigation sector and here is a shorter one distance to go through to the furthest sprinkler:

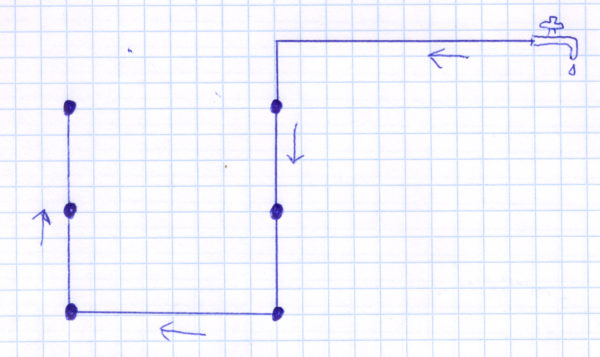

Sprinkler circle

The sprinklers are connected to form a closed circle or ring. The water flows evenly into the pipeline from both sides of the ring, which ensures a more even pressure distribution. It looks like this, for example:

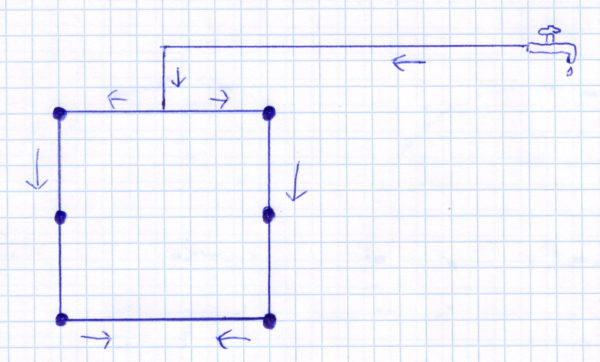

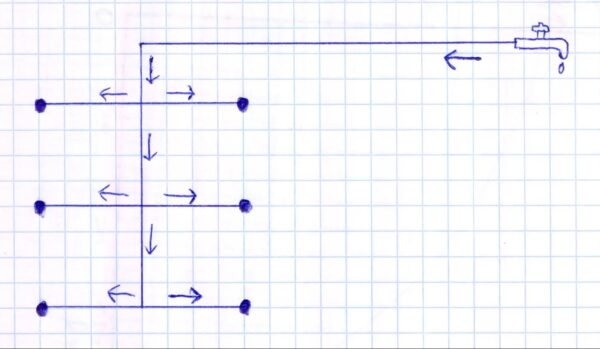

Parallel connection

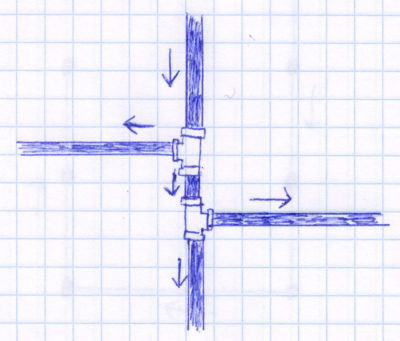

Here, a distribution line is planned in the middle, from which the pipelines to the sprinklers then go in parallel. For our example it looks like this:

On the sketch, this looks simplified as if cross-shaped distributors were attached at the intersections to the sprinklers, which distribute the water in 4 directions. In practice, however, such cross-shaped distributors do not exist; the above is achieved by placing T-pieces one after the other:

A T-piece branching off to the left is immediately followed by a T-piece branching off to the right

Alternative: pressure-regulating sprinklers

The two techniques described above help to achieve the most even pressure distribution possible in the pipeline. However, depending on how the sprinklers are distributed, it can be quite tedious and material-intensive to implement them. An alternative to this is the use of pressure-regulating sprinklers, an innovation that has been offered by major manufacturers for several years. The pressure-regulating sprinklers automatically regulate the pressure to a fixed maximum level and save you a lot of planning work and effort when laying the pipeline.

Example: A sprinkler is pressure regulated at 40 psi. The first sprinkler in the pipeline hits 45 psi of pressure. In the sprinkler, this pressure is reduced to 40 psi. The water continues to the 2nd sprinkler and arrives there with a pressure of 44 psi. Again the pressure in the sprinkler is reduced to 40 psi. This continues until the last sprinkler. In effect, all sprinklers operate at 40 psi. Of course only if the outlet pressure was high enough, i.e. at least 40 psi arrived at the last sprinkler.

This pressure regulation is either built into the sprinkler or it happens through the sprinkler body. Regardless of which nozzle is used in the body, only the maximum pressure permitted by the body reaches the nozzle. Relocating the systems recommended above (sprinkler circle or parallel connection) is therefore no longer absolutely necessary. Instead, the sprinklers can be connected to the pipeline in the easiest way.

Examples of such pressure regulating housings are the Hunter PRS40 (Amazon Link) which regulates to 40psi and the Hunter PRS30 (Amazon Link) which regulates to 30psi.